ANTI-SLIP CARPET MACHINE LINE

There are 2 different types of non-slip carpet manufacturing line in our company. These lines can print at most between 1600 mm and 3200 mm.

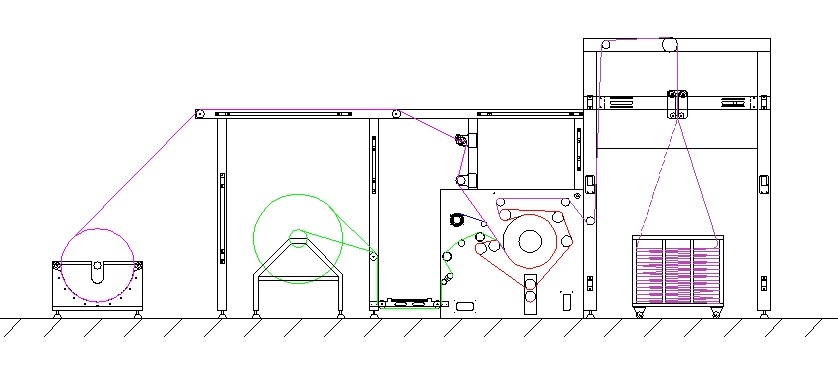

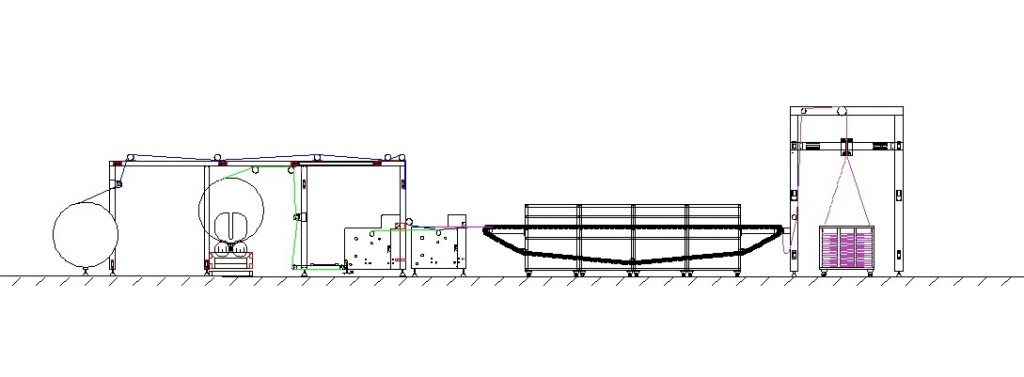

In the first type, there is 1 Lamination Machine, 1 Rotary Printing Machine and 1 Electrical Dryer Machine. In this line, the fabric and felt are laminated with the film.Then it is taken to rotation printing room.İn here, pvc-based anti-slip chemical is applied to the base of the felt,and then the products that are going to dry are cooled and left in the fabric car at the exit.

In the second type, there are 2 Rotary Printing Machines and 1 Electrical Dryer Machine. Unlike the first line, the entire operation is completed on a single line. The advantages of this line are; more economical production takes place by eliminating the cost of the film and saving time because the process is completed on one line.

In this line, when entering the first printing machine to apply the fabric interlining drug,the felt is transmitted to the other machine via the platform. the fabric that emerges from the first printing machine is combined with the felt at the second printing machine entrance,from here two of them enter into the second printing machine and the PVC-based non-slip base drug is applied to the base, the products entering the drying process are cooled and left to the fabric car at the exit.

ROTARY PRINTING MACHINE

-

PRINTING WIDTH 1600mm – 3200mm

-

ONE HEAD ROTARY SCREEN UNIT

-

STAINLESS STEEL BLADE PIPE

-

SCREEN REPORT IS 640 mm

-

PNEUMATIC TEMPLATE STRETCHING

-

PNEUMATIC CHEMICAL PUMP

-

ELECTRONIC SPEED CONTROL

-

PNEUMATIC CLEANING BLADE FOR UNDER CYLINDER

-

FABRIC FEED ROLLER

-

FABRIC TENSIONING CYLINDERS

.

ROTARY SAMPLE PRINTING MACHINE TECHNICIAL SPECIFICATIONS

-

PRINTING WIDTH 1600mm – 3200mm

-

WASHING SYSTEM WITH BRUSH AND SCRAPER

-

BLANKET WITH TENSILE SYSTEM

-

AUTOMATION PLS SYSTEM

-

SERVO ENGINE

-

SPEED CONTROL ( 0-20 m/min )

-

BLANKET WITH SLED SYSTEM

-

MATERIAL ENTRY ASSEMBLY SYSTEM

-

MATERIAL BONDING SYSTEM

-

PRINT SYSTEM BY MAGNETIC STICK or PRINTING BLADE

-

MACHINE HEAD APPARATUS WITH CAPACITY OF PRINTING 64, 82, 91 AND 101 REPORTS

ROTARY PRINTING MACHINE WITH BLANKET

-

PRINTING WIDTH 1600mm – 3200mm

-

TWO SIDES OF MACHINE HEADS

-

WORKING WITH 1-6 COLORS

-

WASHING SYSTEM WITH BRUSH AND SCRAPER

-

BLANKET WITH TENSILE SYSTEM

-

1-6 PNEUMATIC PAINT PUMPS

-

1-6 PAINT RAGLE

-

PAINT LEVEL ELECTRODE

-

AUTOMATION PLS SYSTEM

-

SERVO ENGINE

-

SPEED CONTROL ( 0-30 mt/min )

-

BLANKET WITH SLED SYSTEM

-

MATERIAL ENTRY ASSEMBLY SYSTEM

-

MATERIAL BONDING SYSTEM

-

PRINT SYSTEM BY MAGNETIC STICK

-

MACHINE HEAD APPARATUS WITH CAPACITY OF PRINTING 64, 82, 91 AND 101 REPORTS

-

SUITABLE FOR FLOCK and GLITTER PRINTING

HOT FOIL (EMBOSSING & POLISHING) PRINTING MACHINE TECHNICIAL SPECIFICATIONS

-

PRINTING WIDTH 1600mm-3200mm

-

OPERATING TEMPERATURE 50-250 ° C

-

WORKING SPEED 2-8 m/min

-

CYLINDER DIAMETER 215-270-320-350 mm

-

HYDRAULIC SQUEEZING SYSTEM

-

CLOSE CIRCULATION OIL HEATING SYSTEM

-

DIGITAL TEMPERATURE CONTROL SYSTEM

-

ELECTRONIC METER COUNTER

-

SAFETY ROPE PULL SWITCHES and EMERGENCY STOP BUTTONS

-

ROLL TO ROLL WORKING SYSTEM

-

SUITABLE FOR EMBOSSING and POLISHING PROCESS WITH CHANGING THE CYLINDERS

ELECTRICAL DRYER MACHINE TECHNICIAL SPECIFICATIONS

-

FABRIC WIDTH 1600mm – 3200mm

-

DRYER CABİNET LENGTH IS 12 m

-

4×4 TEFLON DRYING BAND

-

PNEUMATIC BAND CENTERING

-

PNEUMATIC BAND TENSIONING SYSTEM

-

SIDE PANELS CAN BE TOGGLED

-

TOTAL POWER OF INFRARED RESISTANCE IS 120-198 Kw

-

SPECIAL INSULATION MATERIALS IN SIDE PANELS

-

THERE ARE 3 CHIMNEY

COLOR SAMPLE TEST MACHINE TECHNICIAL SPECIFICATIONS

-

PRINTING MEASUREMENTS 800×1000 mm

-

MAGNETIC HAVE 5 STAGE

-

PRINTING WITH MAGNETIC MILL

-

MAGNETIC SPEED CONTROLLED

-

Ø8-10-12-16-20 MAGNETIC MILLS

Flok Atma Makinesi

• En 500-3200 mm

• Döner fırçalı

Kağıt Rotasyon Baskı Makinesi

• Kağıt üzerine flok, transfer baskı ve kesim

PAPER TRANSFER & LAMINATION MACHINE TECHNICIAL SPECIFICATIONS

-

FABRIC WIDTH 1600mm – 3200mm

-

MASTER CYLINDER DIAMETER IS 600 mm

-

HEAT THE MASTER CYLINDER IS OILY CLOSED SYSTEM

-

HEAT THE MASTER CYLINDER WITH RESISTANCE

-

HEAT CONTROL WITH DIGITAL THERMOSTAT

-

RESISTANCE POWER IS 36 Kw

-

FELT IS %100 NOMEX

-

PNEUMATIC FELT TENSION

-

ENGINE POWER IS 4 Kw

-

MANUEL ENGINE CONTROL FOR POWER FAILURE

-

ELECTRONIC SPEED CONTROL

Tek Kafa Rotasyon ve Kaplama Makinesi

• En 1600-3200 mm

• Rapor büyüklüğü 64-101 cm

• Makine hızı 0-40 m/dk

• Makine hız kontrollü

Masa Üzeri Sim Atma -Metraj Sim Atma Ünitesi

Mikser Pat Karıştırma Makinesi

Flat Emboss

Sim ve Flok Atma

Tek Renkli FilmDuruk Baskı Makinesi